How can you effectively plan a medical equipment move? What logistics considerations are crucial for minimizing downtime?

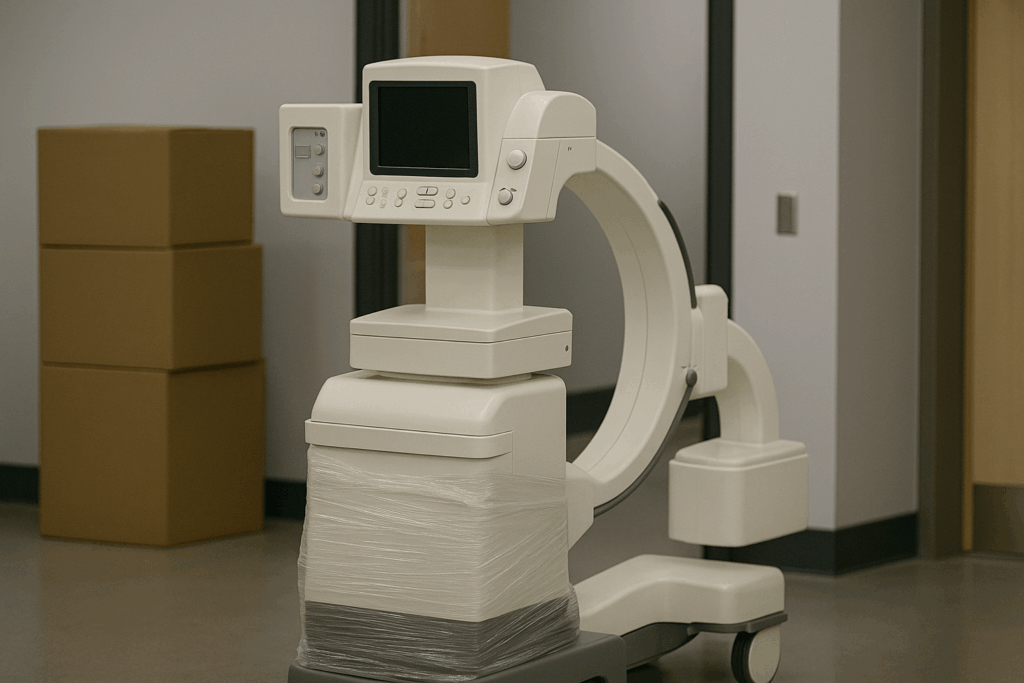

Every medical equipment move must be tailored to the individual equipment and the space where it’s being relocated. As a commercial mover, we work closely with you, the manufacturer’s representative, your staff, property managers, facility managers, and loss control representatives to create a relocation plan well in advance of the project date. This proactive approach is essential in hospital equipment moving projects, where even small delays can impact patient care.

Communication with you is constant throughout the process. We work to minimize downtime by prioritizing items that need expedited service. In some cases, we coordinate phased projects so that redundancy is built into the plan. This ensures not all critical systems are out of service at the same time—a key consideration in healthcare facility relocation.

Our team also considers every logistical detail, including:

- Routes and travel time

- Type of moving equipment required

- Loading dock or ground-level delivery access

- Special hours and building restrictions

- Elevator size and maximum capacity

- Alternative access options such as through-wall openings

- Hoisting and crane services

- Required permits and additional crew training

By carefully planning these factors, we reduce risk, protect sensitive equipment, and keep healthcare facilities operating with minimal disruption. Whether it’s a full-scale hospital equipment moving project or a specialized healthcare facility relocation, the right logistics partner ensures that the transition is smooth, safe, and efficient.