What steps are necessary for post-move equipment verification?

First, we coordinate with you, our valued client, and the manufacturer’s rep to document the current condition and performance of the equipment. This includes reviewing any calibration data or logs that help us establish a baseline. We want to know exactly how the equipment is functioning before the move so the tech can verify and bring it up to specification in the new location.

Pre-Move Steps to Protect Calibration

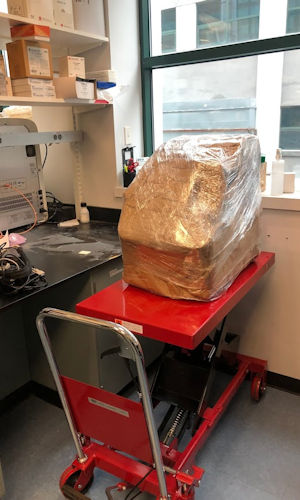

Next, we take extra precautions during transit. For highly sensitive equipment, that often means using climate-controlled vehicles to maintain a stable environment—temperature, humidity, vibration—all of those factors can impact calibration if not properly managed. Our specialty equipped trucks may also include onboard power so equipment can remain plugged in during the trip if required.

Post-Move Verification and Recalibration

Post-move, we work with the client and their equipment technicians to make sure everything is set up properly and restarted under the right conditions. We don’t just drop it off and leave. Often, there’s a need for re-leveling, reconnecting to utilities, or allowing a piece of equipment to acclimate to its new environment before testing can be conducted. From there, it’s all about recalibration and verification. Working with the customer, we make sure the right personnel are on-site to conduct diagnostics and confirm that everything is performing as expected.

Minimizing Downtime and Ensuring Readiness

A good equipment move is about more than just getting from point A to point B—it’s about minimizing disruption and preserving operational readiness. And that’s what we try to do with every move.