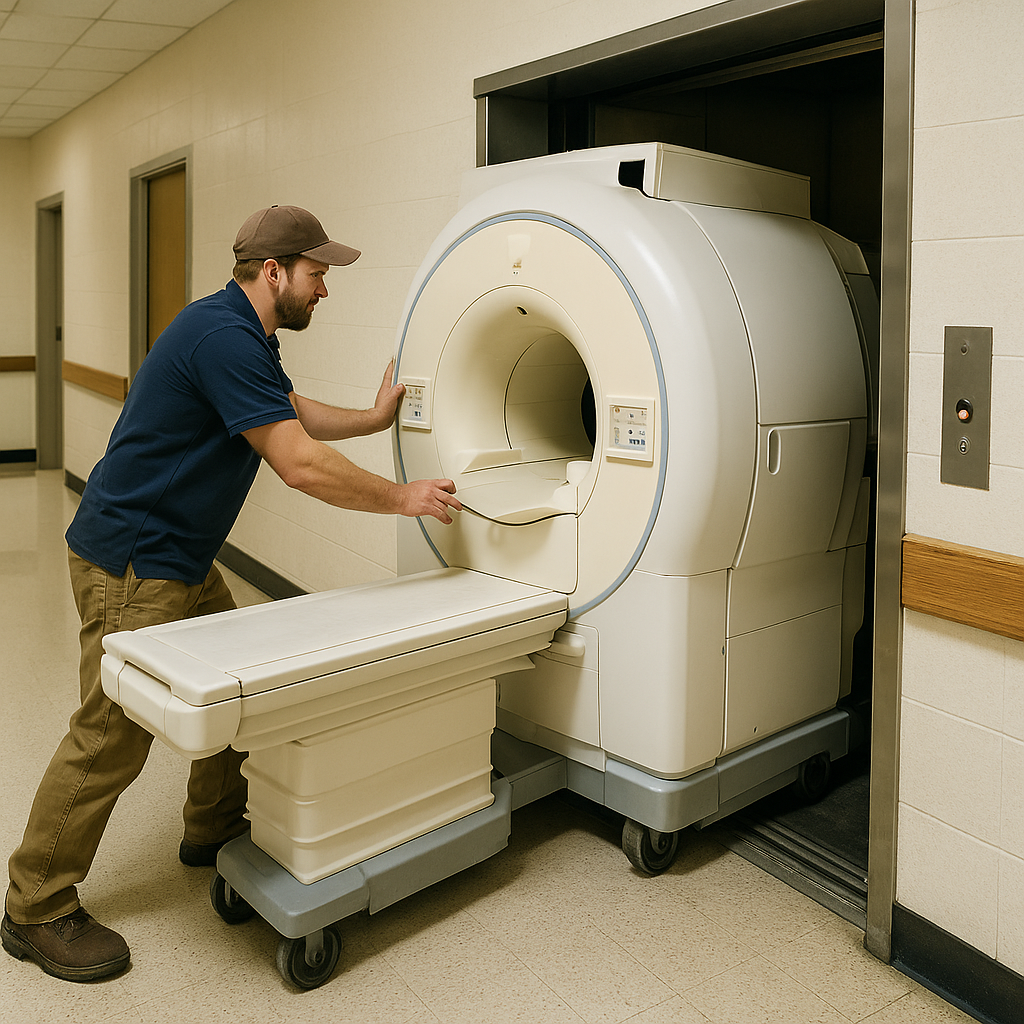

When it comes to relocating medical equipment, the big challenges usually aren’t about distance. Space and access matter more.

You can plan the perfect schedule, have the right team, and even the right trucks, but if you can’t get the equipment through the door, nothing else matters.

When we move a piece of medical equipment—or any move for that matter–we start with a detailed site assessment of both the pickup and delivery locations. This happens before any quotes or timelines are set. And it starts with our team connecting with facility managers, maintenance staff, and sometimes even building owners to understand the full layout and any restrictions.

We prefer a site visit though in some cases, a virtual walkthrough can help us spot potential issues early. Such things as tight corridors, low ceilings, or narrow doorways can completely change a move plan. For example, on one recent project, we discovered that a backloading dock door was only seven feet tall, while the imaging unit we were scheduled to move stood over eight. By catching that in advance, we rerouted the delivery through the main entrance — no delays, no damage, no stress.

We also take elevator logistics seriously. That means verifying dimensions, confirming weight limits, and coordinating with building maintenance so an elevator technician is on call during the move. It’s a small detail that can make a huge difference if something goes wrong mid-lift.

When available, we ask for building layouts and equipment placement plans ahead of time. This allows us to strategize which pieces go in first and how to maintain clear access as the move progresses. For high-value and immobile devices, sequencing is everything.

For moves beyond New England and the northeast, we have some terrific resources. First, the Mayflower network. Second, we also employ advanced virtual tools that make it possible to survey a space remotely — measuring door widths, checking overhangs, and confirming floor clearances. Every inch matters when you’re moving sensitive, high-cost equipment that simply can’t be replaced.

BTI has been in business for four decades. Successful moves aren’t about luck. Just impeccable preparation. By addressing space and access challenges upfront, we keep projects on schedule, equipment protected, and downtime to a minimum.